CALL US AT:

(832) 935-1692

Free Pick-Up & Delivery in USA & CAN

Screw and Barrel Repair Kansas City MO

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

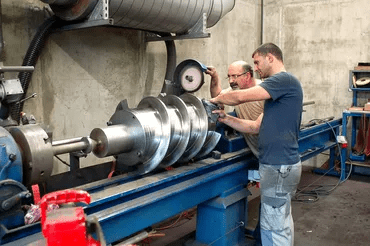

With almost 50 years of screw rebuilding experience, we have developed many of the standard screw building and rebuilding processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

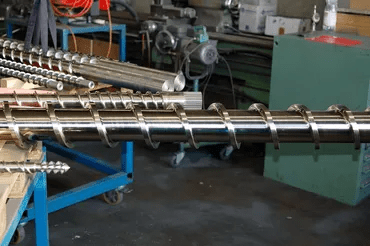

We Can Repair & Recondition All Types Of Industrial Screws

Is your equipment in need of immediate attention? When we receive your screw for rebuilding, our team performs a thorough inspection of the overall condition of your screw which will help us locate and determine the main cause of component failure.

We consider things like how worn the screw flights and root are, what the wear characteristics are, whether or not surface treatment can be improved, SBR’s E.M.T.P (Electro Metal Treating Process) to eliminate wear and pro-long wear life by 6-8 times longer versus OEM, and more.

Repair and rebuild services include flight repairs, root and radius repairs, and also screw tip repairs. When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company.

Screw Repair

Barrel Repair

Gearbox Repair

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Screw Wear & Our Repair Services

The performance of a given plasticating unit is defined by the feed screw’s ability to melt and convey the desired rate and quality of polymer to the die or mold. As the screw flights, channel geometry, and surface treatment wear, performance and quality degrades while energy consumption soars. The overall screw design and materials processed has a major impact on the wear-life of the plasticating unit, so it is vital to monitor screw wear and performance, regardless of application.

Minor wear will have little effect on the overall performance – as machine parameters can be adjusted to maintain productivity. As the radial clearance gap between the screw and barrel increases, energy costs and cycle times rise while rate and quality plummet. To avoid costly downtime it is important for every company to have a robust maintenance program in place. When screw wear isn’t monitored, the overall wear on the screw can become so severe it is no longer economical to rebuild – leaving you with crippling downtime that can ultimately cost more than the components you attempted to salvage.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority. Our services include: Screw and Barrel Repair, Screw Repair, Barrel Repair, Gearbox Repair, Extruder Repair, Extruder Screw Repair, Extruder Screw Flight Repair, Extruder Elements Repair, Extruder Flight Repair, Screw Flight Repair, Feed Screw Repair, Injection Screw Repair, Ball Screw Repair, Conical Screw Repair, Auger Screw Repair, Industrial Screw Repair, Industrial Barrel Repair, Industrial Barrel Resleeve, and more.

Need Immediate Service?

Emergency Screw Repair

As an added service, we offer emergency repair in Kansas City MO and in all nearby areas. Broken screw? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, Screw And Barrel Repair can help.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

Screws We Service But Are Not Limited To:

Extruder Screws

Feed Screws

Injection Screws

Ball Screws

Conical Screws

Auger Screws

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Call Us For Screw And Barrel Repair & Rebuild Done Right!

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

-

What types of screws and barrels do you repair?

We repair all types of screws and barrels, including extruder screws, feed screws, injection screws, ball screws, conical screws, and auger screws.

-

How do I know if my screw or barrel needs repair?

Signs of wear include decreased performance, increased energy consumption, and noticeable damage to the screw flights or barrel surface.

-

What is the typical turnaround time for repairs?

Our standard lead time is typically between 10-14 days, depending on the specific work required.

-

Do you offer emergency repair services?

Yes, we offer emergency repair services for situations where immediate attention is needed.

-

What are the common causes of wear in extruder screws and barrels?

Common causes of wear include abrasive materials, high temperatures, and prolonged usage without proper maintenance.

-

How can I optimize the performance of my injection screws?

Optimizing performance involves regular monitoring of wear, adjusting processing parameters, and considering upgrades or enhancements such as coatings or design modifications.

-

What measures can be taken to minimize wear in feed screws for plastic extrusion?

Minimizing wear involves selecting appropriate materials, maintaining proper alignment, and implementing preventive maintenance schedules.

-

Are there specific maintenance routines for auger screws used in material handling applications?

Yes, regular cleaning, inspection for wear or damage, and lubrication are essential maintenance routines for auger screws in material handling applications.

-

What are the implications of wear in ball screws for precision machinery?

Wear in ball screws can lead to decreased precision, increased backlash, and reduced overall performance of precision machinery.

-

How does wear in conical screws impact the efficiency of mixing and compounding processes?

Wear in conical screws can result in uneven mixing, reduced throughput, and increased energy consumption, affecting the efficiency of mixing and compounding processes.

-

Can you repair screws and barrels for specialized applications such as food processing or medical devices?

Yes, we have experience repairing screws and barrels for specialized applications, ensuring compliance with industry regulations and standards.

-

What are the benefits of using specialized coatings for screws and barrels in corrosive environments?

Specialized coatings can provide corrosion resistance, prolonging the lifespan of screws and barrels in corrosive environments and reducing maintenance costs.

-

How does wear in screw tips affect the quality of molded products in injection molding?

Wear in screw tips can lead to inconsistencies in melt quality, increased reject rates, and decreased product quality in injection molding processes.

-

What steps can be taken to extend the wear life of screws and barrels in high-wear applications such as compounding or recycling?

Steps include selecting wear-resistant materials, optimizing processing parameters, and implementing regular maintenance practices tailored to the specific application.

-

What is the Electro Metal Treating Process (EMTP) and how does it benefit my equipment?

EMTP is a process that enhances wear life by 6-8 times longer compared to OEM treatments, resulting in increased durability and performance for your equipment.

-

Do you offer a warranty?

Yes! Our 72-month in-use warranty covers all repairs performed by our team, providing peace of mind and assurance of quality workmanship.

-

Do you repair gearboxes as well?

Yes, we specialize in rebuilding all makes and models of gearboxes, both domestic and foreign.

-

Can you work with both domestic and foreign gearbox models?

Absolutely, our expertise extends to repairing gearboxes from various manufacturers worldwide.

-

What are the key indicators of screw and barrel wear?

Key indicators include decreased productivity, increased energy consumption, and visible signs of wear on screw flights and barrel surfaces.

-

Do you offer on-site repair services?

We primarily operate from our repair facility and we provide shipping and logistics support for your convenience, but arrangements can be made for on-site repair services if the situation requires it!

-

What are the advantages of repairing screws and barrels over replacement?

Repairing screws and barrels is often more cost-effective than replacement and can extend the lifespan of your equipment significantly.

-

Can you repair screws and barrels for specialized machinery or unique applications?

Yes, we have experience working with a wide range of machinery types and applications, including specialized and custom equipment.

-

Do you provide shipping and logistics support for sending and receiving equipment?

Yes, we offer FREE shipping and logistics support to ensure safe transportation of your equipment to and from our facility.

-

How do I get started with requesting a repair service?

Simply contact us via phone or email to discuss your repair needs, and our team will guide you through the process!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

More Areas We Service

Neighborhoods We Service In Kansas City MO

Crossroads Arts District, Royal View Meadows, West Waldo West, Ivanhoe, Claremont North Estates, Stratford Gardens West Estates, Sunset Hill, Strawberry Hill (in nearby Kansas City, Linden Hills and Indian Mound, Faxon, Palestine Westport, West Plaza, Blue Hills, Tower Homes North, Tower Park West, Claremont West Estates, Highland View, Ivanhoe, Southmoreland Place, Timber Valley West Estates, Brown Estates, Hickman Mills, Parkville, Claremont East Estates, Stratford Circle South Estates, North Hyde Park, West Bottoms, Stratford Estates North, Hillcrest Manor, Romanelli West, Columbus Park, Hillcrest, Country Lane Estates, Ridgefield, Eastwood Hills West, Country Club Plaza, Linden Hills, Beacon Hill, Bridlespur, Eastern 49-63 West, Timber Valley Southwest Estates, Tower Homes West, Pershing Heights South, Volker, Rockhill, Swope Parkway-Elmwood, Eastern 49-63, Overland Park, Mission Ridge, Winnwood, Gladstone), Pendleton Heights, Fairwood and Robandee West, Ruskin Heights, Blue Valley Park, Stratford Place North, Maple Park West, Eastern 49-63 North, Pendleton Heights, Longfellow, Midtown, Westwood Hills, Stratford Circle West Estates, Mount Cleveland, Stratford Circle East Estates, Waldo, Highview Estates South, Timber Valley Southeast, Stratford Estates South, Flinthills, Western Hills, Flora South, Santa Fe Hills, Tower Park South, Park Central-Research Park, Ruskin Hills, Bonne Hills, Stratford Estates East, Ruskin Hills, Timber Valley South, Stratford Estates, Sunset Hill, Quality Hill, Union Hill, Blue Ridge Farms, Sheffield South, West Plaza, Blue Valley, Northland (includes neighborhoods like North Kansas City, North Blue Ridge, Meadowbrook Manor East, Ruskin Place, 39th Street West, Ivanhoe Southeast, Terrace Lake Gardens North, Claremont South Estates, Santa Fe, Western 49-63, Claremont North Estates, Kansas), Fairwood and Robandee South, Lea Manor, Eastwood Hills, Fairwood and Robandee, Old Northeast, Western Hills South, Stratford Circle North, Saint Catherine's Gardens East, Scarritt Renaissance, Fairlane, Blue Valley Industrial, Wendell Phillips, Eastern 49-63 South, East Meyer, Marlborough, Stratford Circle East Estates, Swope Park, Lykins, Ivanhoe Southeast South, Timber Valley North Estates, Marion Park, North Kensington, Robandee South, Blue Hills South, Melody Hills, Ruskin Place North Estates, Downtown, Timber Valley Southeast Estates, Pendleton Heights Historic District, Foxtown East, Palestine East, Ivanhoe Northeast, Timber Valley West, Hospital Hill, Vineyard Estates, Westside North, Stratford Circle East, Fairwood and Robandee North, Waldo, Knoches Park, Ruskin Place South Estates, Fairlane, Waldo Homes, Sunset View, Stayton Place North Estates, Cunningham Ridge, Highview Estates North, Robandee South Estates, South Town Fork Creek, West Plaza North, Sheffield, Ruskin Place South Estates, Pershing Heights, Swope Park Campus, Ward Parkway, Stayton Meadows, White Oak West Estates, Bannister Acres, Santa Fe Place, Tower Park West Estates, Stratford Place South, Stayton Place East, Mission Lake South, Leeds, Hanover Place, Park Hill, South Plaza, Coleman Highlands, Winchester, Stratford Gardens East Estates, Meadowbrook Manor West Estates, Park Central North, Western Hills North, Mount Cleveland, Cunningham Ridge, Claremont East, Stayton Place West, Vineyard, Stratford Gardens North Estates, Brookside, Oak Park Southeast, White Oak West, White Oak, River Market, Westport, Ruskin Place West, Red Bridge, Hyde Park, Hidden Valley, Marlborough East, Martin City, Briarcliff, Tower Park Estates, Sunset Hills, Red Bridge East, Hidden Valley, Crown Center, Westside South, Armour Hills, Oak Meyer Gardens

ZIP Codes We Service In Kansas City MO

64127, 64129, 64106, 64108, 64132, 64117, 64105, 64101, 64123, 64109, 64133, 64052, 64125, 64126, 64113, 64119, 64110, 66101, 64128, 64111, 64050, 64130, 64118, 66206, 64124, 64161, 66205, 64116, 64151, 66115, 64114, 64120, 64102, 64112, 66208, 64053, 64103, 66105, 66229, 64115, 66103, 66118

Quick Menu

Services

» Screw & Barrel Repair

» Extruder Repair

» Gearbox Repair

» and more!

Hours

Mon 09:00 am – 05:00 pm

Tue 09:00 am – 05:00 pm

Wed 09:00 am – 05:00 pm

Thu 09:00 am – 05:00 pm

Fri 09:00 am – 05:00 pm

Sat Closed

Sun Closed

© All Rights Reserved | Screw And Barrel Repair (Subsidiary Of Precision Gear Repair)