CALL US AT:

(832) 935-1692

Free Pick-Up & Delivery in USA & CAN

Feed Screw Repair

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

With almost 50 years of repair and rebuild experience, we have developed many of the standard processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

Expert Feed Screw Repair To Enhance Your Machinery's Longevity & Efficiency

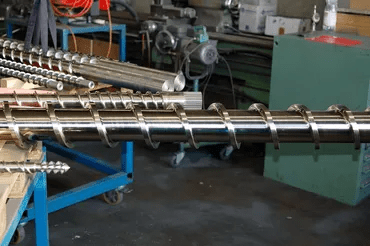

Specializing in the meticulous restoration of worn, damaged, or non-functioning feed screws, our expert technicians ensure your machinery operates at peak efficiency. Feed screws are crucial components in various industries, including plastics, rubber extrusion, and injection molding, where precision and reliability are paramount.

Our feed screw repair service addresses common issues such as wear, abrasion, and corrosion, which can significantly impede your equipment's performance and output quality. Using advanced techniques like precision machining, weld repair, and thermal spraying, we restore your screws to their original specifications or better. This not only extends the life of your machinery but also enhances process stability and material throughput, reducing downtime and increasing your operational productivity.

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Our Feed Screw Repair Services

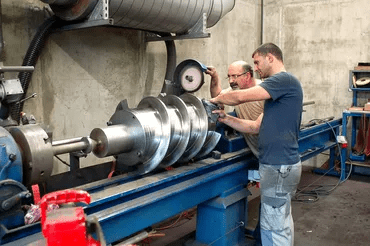

At Screw And Barrel Repair, our feed screw repair process is meticulously designed to restore your essential machinery components to optimal conditions, utilizing industry-leading techniques and technologies. The process begins with a comprehensive assessment of your feed screw, where we use precision measurement tools to gauge wear patterns, damage extents, and geometrical accuracy. Commonly identified issues include flight wear, root wear, and drive-end damage. This initial inspection helps us determine the specific repair needs and tailor our approach accordingly.

Once the assessment is complete, our technicians employ advanced repair techniques. For severely worn screws, we often perform a process known as flight rebuilding, which involves adding weld material to the flights and then precision machining them back to OEM specifications. This is complemented by chrome plating or thermal spraying with tungsten carbide to enhance the wear resistance of the screw surfaces. These techniques not only restore the screw to its original condition but can also extend its lifespan beyond that of its initial fabrication.

The final step involves precision grinding and polishing to ensure the feed screw meets the exact dimensional tolerances required for your specific machinery. This stage is crucial for maintaining the efficiency of the screw in material processing, ensuring smooth, consistent product output with minimal downtime. Throughout the repair process, we maintain rigorous quality control checks to guarantee that each refurbished screw delivers enhanced performance and reliability. This attention to detail ensures that your operations can resume swiftly with improved throughput and reduced material waste.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority.

Need Immediate Service?

We Offer Emergency Repair 24/7 - Call Us Anytime!

As an added service, we offer emergency repair services nationwide. Broken equipment? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, we can help!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When equipment is rebuilt properly, it can often be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

-

How long does the feed screw repair process typically take?

The duration of the repair process can vary depending on the extent of the damage and the specific requirements of your machinery. Generally, repairs can be completed within 1 to 2 weeks. For urgent requirements, we also offer expedited services to ensure minimal downtime for your operations.

-

What kind of wear and damage can you repair on a feed screw?

We can address a wide range of wear and damage, including abrasive wear, adhesive wear, corrosive wear, and mechanical damage such as breaks and cracks. Our techniques are effective on various damages whether they occur on the flights, root, or drive-end of the screw.

-

Can you upgrade my feed screws to better resist wear and corrosion?

Absolutely, during the repair process, we can enhance the original design of your feed screws with advanced coatings such as chrome plating or tungsten carbide thermal spraying. These upgrades significantly increase the resistance of your screws to wear and corrosion, thereby extending their operational lifespan.

-

Do you provide warranties for repaired feed screws?

Yes, we stand behind the quality of our work. All repaired feed screws come with a warranty covering material defects and workmanship. The specific terms and duration of the warranty can be discussed during the repair consultation based on your needs.

-

Is it more cost-effective to repair a feed screw or replace it?

Repairing a feed screw is generally more cost-effective than replacing it, especially when considering high-performance screws designed for specific applications. Our repair services restore screws to their original or better specifications, offering a significant cost saving over replacement, without compromising on performance or longevity.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

More Services We Provide

Quick Menu

Services

» Screw & Barrel Repair

» Extruder Repair

» Gearbox Repair

» and more!

Hours

Mon 09:00 am – 05:00 pm

Tue 09:00 am – 05:00 pm

Wed 09:00 am – 05:00 pm

Thu 09:00 am – 05:00 pm

Fri 09:00 am – 05:00 pm

Sat Closed

Sun Closed

© All Rights Reserved | Screw And Barrel Repair (Subsidiary Of Precision Gear Repair)