CALL US AT:

(832) 935-1692

Free Pick-Up & Delivery in USA & CAN

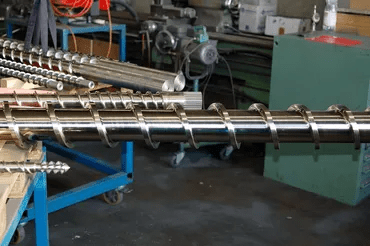

Ball Screw Repair

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

With almost 50 years of repair and rebuild experience, we have developed many of the standard processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

Precise and Efficient Ball Screw Repair Services

Ball screws, essential components in precision machinery, are vital for converting rotational motion into linear motion with minimal friction. Over time, wear and tear can lead to issues such as backlash, diminished accuracy, and system failure, which are detrimental in CNC machines, robotics, and aerospace equipment.

Our specialized repair process addresses common problems including ball screw wobble, thread grinding, and premature wear. By restoring your ball screws to their original specifications, we help you avoid the costly downtime and replacement expenses associated with continued degradation. Utilizing advanced techniques such as precision grinding and expert assembly, we ensure that your machinery maintains peak performance with enhanced durability and reliability. Trust us to extend the lifespan and efficiency of your essential equipment, minimizing operational disruptions and maintaining your productivity.

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Our Ball Screw Repair Services

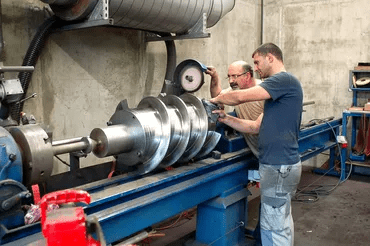

At Screw And Barrel Repair, our Ball Screw Repair service is meticulously designed to ensure your precision machinery operates at its optimal level. The repair process begins with a comprehensive evaluation of the ball screw assembly, where we analyze the helical raceway, nut, and ball bearings for signs of wear and tear. This initial inspection is critical as it determines the extent of damage and the specific restoration actions required.

Utilizing advanced metrology tools, we measure the lead accuracy and axial play to pinpoint deviations from OEM specifications. Should we find inconsistencies, our skilled technicians employ precision thread grinding to restore the threads to their precise geometric tolerances. This step is crucial for eliminating backlash and improving the smoothness of the linear motion, thereby enhancing overall machine accuracy.

Once the thread grinding is complete, we proceed to replace worn ball bearings with high-grade, preloaded balls that match or exceed original specifications. This replacement is vital for maintaining the structural integrity of the ball screw and ensuring efficient load distribution and reduced friction. The assembly is then lubricated with industry-specific, high-performance grease, which plays a significant role in minimizing wear and extending the lifespan of the ball screw.

Finally, we conduct a rigorous testing phase that includes dynamic load testing and speed trials to ensure that the repaired ball screw meets all functional and performance criteria. Only after these tests confirm that the ball screw operates within required parameters do we consider the repair complete. Our thorough approach not only restores your ball screw to its original condition but also significantly extends its service life, ensuring your machinery continues to perform with exceptional precision and reliability.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority.

Need Immediate Service?

We Offer Emergency Repair 24/7 - Call Us Anytime!

As an added service, we offer emergency repair services nationwide. Broken equipment? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, we can help!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When equipment is rebuilt properly, it can often be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

-

How long does the ball screw repair process typically take?

The duration of the repair process can vary depending on the extent of damage and the specific requirements of your ball screw assembly. Typically, repairs are completed within 1 to 2 weeks. We also offer expedited services for urgent repairs to minimize your downtime.

-

What types of ball screws can you repair?

We are equipped to repair a wide range of ball screws from various machinery and industries, including CNC machines, robotics, aerospace, and more. Our technicians have experience with both metric and imperial units, and we handle brands and models from all major manufacturers.

-

Is it cost-effective to repair a ball screw rather than replace it?

Yes, repairing a ball screw is generally more cost-effective than replacing it, especially for high-precision or large-scale machinery. Repairing can save up to 50% compared to the cost of new replacements, not including the additional time and expense involved in sourcing and fitting a new unit.

-

Do you offer any guarantees on the repairs?

We stand by the quality of our work with a comprehensive warranty on all repairs. This warranty covers both parts and labor, ensuring your ball screw operates flawlessly post-repair. The specific terms of the warranty can be discussed during the evaluation of your repair needs.

-

Can you provide on-site repair services for ball screws?

While the majority of our repairs are conducted in our fully equipped facility, we do offer on-site repair services for cases where disassembly and transport of the ball screw would be impractical or too costly. Our on-site services include inspection, minor repairs, and adjustments to ensure minimal disruption to your operations.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

More Services We Provide

Quick Menu

Services

» Screw & Barrel Repair

» Extruder Repair

» Gearbox Repair

» and more!

Hours

Mon 09:00 am – 05:00 pm

Tue 09:00 am – 05:00 pm

Wed 09:00 am – 05:00 pm

Thu 09:00 am – 05:00 pm

Fri 09:00 am – 05:00 pm

Sat Closed

Sun Closed

© All Rights Reserved | Screw And Barrel Repair (Subsidiary Of Precision Gear Repair)