CALL US AT:

(832) 935-1692

Free Pick-Up & Delivery in USA & CAN

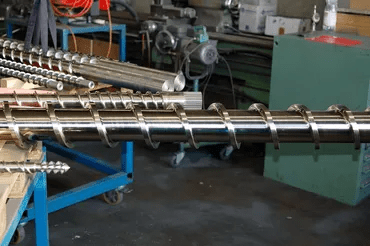

Industrial Barrel Resleeve

Industrial Repair & Rebuild Services To Reduce Downtime and Lower Costs

With almost 50 years of repair and rebuild experience, we have developed many of the standard processes used in the industry today. Trust our team with your production. Your Satisfaction Is Our Motivation!

Revitalize Your Equipment with Industrial Barrel Resleeve Services

We specialize in the essential service of Industrial Barrel Resleeving, a precise solution tailored for businesses relying on extrusion and injection molding machinery. Over time, the internal surfaces of barrels can suffer from wear and tear due to abrasion, corrosion, or the processing of aggressive materials, leading to decreased efficiency and product quality.

Our Industrial Barrel Resleeve service addresses these common issues by replacing the worn inner diameter of your barrels with a new, durable liner. This not only restores your barrel to its original specifications but also extends its lifespan significantly, ensuring your operations run smoother and reducing downtime. By choosing to resleeve rather than replace, you optimize both cost-efficiency and equipment performance, keeping your production lines at peak efficiency with minimal interruption.

We work with brands including Milacron, Kraus Maffei, Welex, Maplin, Battenfeld-Cincinnati, Sterling, Werner Pfleiderer, Davis Standard, NRM, Coperion, and many more.

Consider the cost of replacement vs. repair before making the decision to purchase new equipment. We offer a 72 month in-use warranty!

About Our Industrial Barrel Resleeve Services

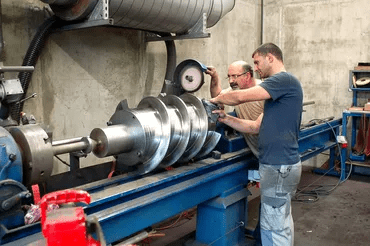

Industrial Barrel Resleeve is a meticulous process that requires expertise and precision to ensure optimal results. The process begins with a thorough assessment of the damaged barrel, where our skilled technicians inspect for wear, corrosion, and other signs of deterioration. Advanced diagnostic tools and techniques are employed to accurately identify the extent of the damage and determine the best course of action.

Once the assessment is complete, the damaged barrel lining is carefully removed using specialized equipment such as precision cutting tools and machining techniques. This step is crucial to prepare the barrel for re-sleeving and involves meticulous attention to detail to avoid further damage to the equipment. Our technicians are highly trained in handling a variety of barrel materials, including steel, aluminum, and various alloys, ensuring compatibility and durability of the re-sleeving process.

After the old lining is removed, the barrel is thoroughly cleaned and prepared for the application of the new sleeve. The selection of the sleeve material is critical to ensure optimal performance and longevity of the repaired barrel. We utilize high-quality materials such as nitrided steel, bimetallic alloys, and ceramic coatings, depending on the specific requirements of the application and the operating conditions of the equipment.

Once the new sleeve is applied, our technicians meticulously inspect the barrel to ensure proper fit, alignment, and functionality. Quality control measures are implemented throughout the process to maintain the highest standards of workmanship and integrity. Upon completion, the re-sleeved barrel is ready to be installed back into the equipment, restoring its functionality and extending its lifespan for years to come.

With nearly five decades of expertise in the field, we stand as pioneers in developing the industry's standard processes for screw rebuilding. When you choose Screw and Barrel Repair, you're not just choosing a service provider; you're partnering with a team of dedicated professionals who are passionate about delivering superior quality and unmatched reliability. Experience the difference with Screw and Barrel Repair - where precision meets perfection, and your satisfaction is our top priority.

Need Immediate Service?

We Offer Emergency Repair 24/7 - Call Us Anytime!

As an added service, we offer emergency repair services nationwide. Broken equipment? Is emergency repair needed? We are an authorized emergency service repair shop. We are willing to work overtime on your job until it is completed, giving you the fastest delivery time in the industry. Delivery time depends on the specific work to be performed. Whatever your repair needs are, no matter how big or small, we can help!

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When equipment is rebuilt properly, it can often be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

We make the repair process easy

1

Contact Us Via Phone or Send Us A Message Online

Get in touch with us effortlessly by phone or through our convenient online messaging system.

2

Free Pick-Up & Delivery Anywhere In The USA & Canada

Enjoy complimentary pick-up and delivery services spanning across the USA and Canada.

3

Top-Tier Service With Industry-Leading Turnaround Time

Experience superior service with turnaround times that set the industry standard.

Frequently Asked Questions

Please reach us at (832) 935-1692 if you cannot find an answer to your question.

-

How long does the Industrial Barrel Resleeve process take?

The duration of the Industrial Barrel Resleeve process can vary depending on factors such as the extent of damage to the barrel, the complexity of the equipment, and the availability of materials. Typically, the process can take anywhere from a few days to a couple of weeks to complete. However, we strive to minimize downtime for our clients and provide efficient turnaround times without compromising on quality.

-

What types of industries benefit from Industrial Barrel Resleeve services?

Industrial Barrel Resleeve services are beneficial for a wide range of industries that rely on equipment with barrel components, including plastics manufacturing, rubber processing, food and beverage production, chemical processing, and many others. Any industry utilizing extrusion, injection molding, or similar processes can benefit from our expertise in re-sleeving industrial barrels.

-

Is Industrial Barrel Resleeve a cost-effective solution?

Yes, Industrial Barrel Resleeve is a cost-effective solution compared to the alternative of replacing the entire barrel or purchasing new equipment. By re-sleeving the damaged barrel, you can extend the lifespan of your equipment, avoid costly replacements, and minimize downtime associated with repairs. Our efficient re-sleeving process helps you maximize the value of your investment in industrial equipment.

-

What materials are used for re-sleeving industrial barrels?

We utilize a variety of high-quality materials for re-sleeving industrial barrels, including nitrided steel, bimetallic alloys, ceramic coatings, and other specialized materials. The selection of the sleeve material is based on factors such as the specific requirements of the application, the operating conditions of the equipment, and the desired performance characteristics.

-

Can you resleeve barrels of different sizes and configurations?

Yes, our Industrial Barrel Resleeve services are tailored to accommodate barrels of various sizes, configurations, and materials. Whether you have a small-diameter extruder barrel or a large-scale injection molding machine, our experienced technicians have the expertise and capabilities to resleeve barrels to meet your specific requirements.

Request A Free Quote or Emergency Repair Service!

Is your equipment in need of immediate attention? When a screw is rebuilt properly, without narrowing flight widths, the screw can be rebuilt time and time again, resulting in massive savings for your company. Call Screw And Barrel Repair for repair and rebuild services done right.

More Services We Provide

Quick Menu

Services

» Screw & Barrel Repair

» Extruder Repair

» Gearbox Repair

» and more!

Hours

Mon 09:00 am – 05:00 pm

Tue 09:00 am – 05:00 pm

Wed 09:00 am – 05:00 pm

Thu 09:00 am – 05:00 pm

Fri 09:00 am – 05:00 pm

Sat Closed

Sun Closed

© All Rights Reserved | Screw And Barrel Repair (Subsidiary Of Precision Gear Repair)